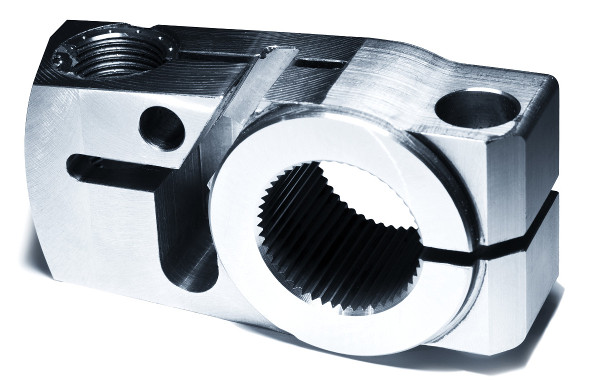

Turning

The two-turret and three-turret turning centers are served by anthropomorphic robots for high production even during unattended shifts. We can carry out turning operations up to a maximum diameter of 340 mm and a maximum length of 420 mm. Since the machines are equipped with driven tools and Y-axis, we can perform phase machining with excellent precision and for everything that cannot be done by the machinery, we can use the milling department by building equipment for the timing of mechanical parts.

All processes are performed with certified raw materials:

Ferrous Materials – Stainless Steel (Aisi 303/304/316/410/416/420) – Aluminium

Bronze – Brass – BOHLER – Monel / Inconel / Hastelloy / Duplex / Superduplex / Titanium

Milling and Drilling

The vertical machining centers have maximum strokes X1000 Y500 Z500 with the possibility of using a fourth continuous rotary axis. In addition to the precision of the piece, the horizontal Pallet changers guarantee high productivity. The maximum strokes are X700 Y700 Z600.

All processes are performed with certified raw materials:

Ferrous Materials – Stainless Steel (Aisi 303/304/316/410/416/420) – Aluminium

Bronze – Brass – BOHLER – Monel / Inconel / Hastelloy / Duplex / Superduplex / Titanium

Grinding

The external adjustments cover a range of products that reaches a maximum external diameter of 290 mm. with a maximum length of 600 mm. Those for internal use can grind pieces with a minimum diameter of 8 mm. up to a maximum diameter of 200 mm. with a length not exceeding 100 mm.

All processes are performed with certified raw materials:

Ferrous Materials – Stainless Steel (Aisi 303/304/316/410/416/420) – Aluminium

Bronze – Brass – BOHLER – Monel / Inconel / Hastelloy / Duplex / Superduplex / Titanium